Xaap Overview

Learn about Xaap, a subscription based inspection reporting app that streamlines building fire and life safety compliance.

Sprinkler Manufacturers: Johnson Controls

Reprinted from FPC/Fire Protection Contractor Magazine • May 2022 Edition

About: Effective fire suppression is a multi-faceted challenge that demands a wealth of products, systems, and knowledge. Johnson Controls has long been a leader in this vital element of helping to protect people and property. In fact, the company invented the very first sprinkler more than a century ago and have been delivering expertise, innovations, and service to our customers ever since. Today, we manufacture, configure, and install an unmatched range of fire suppression solutions including sprinklers and valves, extinguishers and agents, special hazards systems, related components, and fittings. We serve large, multi-site projects through a network of design centers of excellence. We provide software that helps users design and configure systems to meet their unique requirements. Fire suppression solutions from Johnson Controls can help you meet your most vital mission: safety.

Our brands: The Johnson Controls fire suppression portfolio is built on more than 130 years of experience in fire protection innovation, and includes some of the most trusted product brands in the industry, including TYCO® fire sprinklers and valves, RAPID RESPONSE residential fire sprinkler systems, SPRINKCAD design software, GRINNELL G-Fire grooved couplings and fittings, and foam concentrates and hardware from ANSUL® and CHEMGUARD.

Innovation: Johnson Controls is an innovation-driven company committed to constantly advancing the possibilities in fire protection. From the invention of the very first automatic f ire sprinkler by Frederick Grinnell to electronically operated sprinkler systems and UL Listed antifreeze, Johnson Controls has remained an industry leader. Our culture of innovation and continuous improvement drives us to solve today’s challenges while constantly asking ‘what’s next’.

JOHNSON CONTROLS celebrated a milestone as the Xaap Compliance Reporting Platform surpasses one million building inspections.

Since 2018, facility managers and their teams have used the Xaap compliance reporting software to test nearly 55 million individual building devices, including f ire alarms, extinguishers, security devices, sprinklers, and other systems across North America. Xaap has helped these customers identify more than 500,000 deficiencies within their building systems, uncovering many opportunities to improve building safety and compliance.

“At Xaap, we’re working to digitize all inspection types to help keep people and assets safe,” said Evan Bombino, Sales Director, New Product Technology, Global Fire Detection Products at Johnson Controls. “As we surpass one million inspections and over 500,000 deficiencies documented, we’re excited by the prospect of how this large set of Xaap data will help us optimize experiences for users and allow us to offer improved smart building products.”

Xaap is a mobile- and web-based building inspection reporting application that provides a single, centralized platform for tracking, maintaining, and reporting building system compliance. The mobile app allows inspectors to capture inspection data and generate reports directly from their mobile devices. Xaap is designed to help make the lives of inspectors, technicians, service managers, back-office teams, facility managers, and building owners easier. By streamlining the inspection process through a variety of smart application features, Xaap helps deliver accurate and efficient inspection reporting.

Key features include ready-to-use and customizable report templates, digital signature capture, barcoding, inventory management, a historical report repository, a deficiency dashboard, and an analytics dashboard. With a shared source of data, building teams can collaborate seamlessly, stay better coordinated, and operate in sync.

In addition to providing more accurate and efficient inspection reporting, Xaap also empowers building and facility managers, inspectors, and technicians with powerful control and insights. This includes digital access to inspection reports and other facility documents 24/7, a centralized view of systems and compliance data, the ability to establish permissions, and the data that can be leveraged to increase efficiency, lower costs, and improve safety and security.

Xaap plans to further evolve the platform offerings for the future, including features that allow users to schedule, dispatch, and track inspections and repairs to help ensure inspections aren’t overlooked and deficiencies are addressed promptly. As more data is gathered through the Xaap platform, insights from the dashboard will continue to improve and more accurately pinpoint emerging trends and KPIs.

Xaap is available on the App Store and Google Play.

For more information visit: www.xaapbuildings.com.

Beyond the File Cabinet:

Fire Protection System Testing and the Cloud

Tyler Brown

Many inspections of fire protection systems are still taking place on paper in an Excel file or an editable PDF. The fire protection industry has been historically slow when it comes to adopting new technology, so this shouldn’t come as a shock. Here are the benefits of a digital inspection process to convince doubters that the fire protection industry belongs in the 21st century.

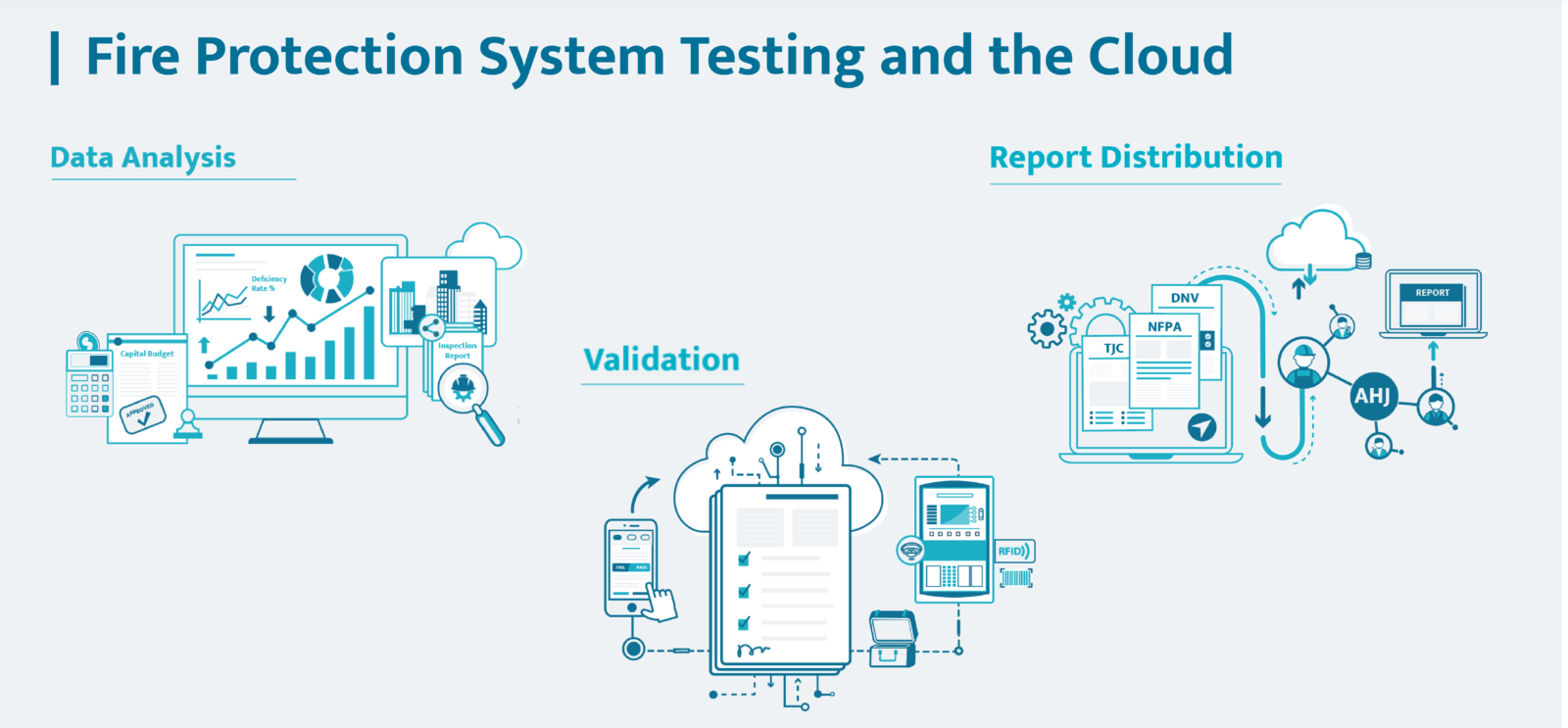

Validation

For as long as fire protection systems have been in buildings, there have been regulatory requirements for inspection, testing, and maintenance (ITM). Historically, there has been an unspoken understanding that the technician would perform what they said they performed, but in an industry where accurate reports mean potentially saving lives, is that enough? Technology can play a role in reducing the level of doubt that a customer or authority having jurisdiction/code official may endure when reviewing an inspection report. Here are three main ways an inspection report can be validated:

- Barcoding. This is a great technology that allows service providers and facility managers to more accurately track and maintain inventory. When barcodes are placed on fire protection assets and scanned as a part of the ITM process, the implication is that the technician was at least within a certain proximity of the device. However, this process isn’t flawless. There still is no verification the device was actually tested and an alarm was actually received. Additionally, barcodes can be copied and replicated, which means the so"ware could still show a barcode was scanned, but nobody actually visited or tested the device.

- RFID. As an emerging technology in the compliance management industry, RFID is showing promising results. It provides a more efficient experience to the technician, without need to scan a physical barcode. However, it isn’t as cost effective as barcoding, and until RFID is worked into the manufacturing of fire alarm equipment, it’s hard to imagine a world where this has wide-scale acceptance.

- System Connectivity. This is the gold standard of a fully validated ITM process, which relies on a panel to indicate devices are working the way they are expected to work. This approach does not come without limitations. Specifically, it requires the manufacturer to provide system connectivity, which is quite limited in the compliance-reporting market today. Additionally, this approach is limited to electronic systems such as fire alarm and the other system components that report back to an electronic system. As system and device connectivity is on the rise, it is anticipated that the concept around a connected ITM activity will increase in prevalence. However, this shouldn’t prevent ensuring the service provider is using some form of validation in the inspection processes. The bottom line is that with the stakes as high as they are, validation should be expected to provide peace of mind.

Data Analytics

The impact of data is often talked about in esoteric terms that make it difficult to visualize specifically how it could benefit an organization, so it’s important to establish a few use cases where data can have a tremendous impact.

- Frequencies of inspection. Currently, the institutions that provide recommendations on testing frequencies don’t have a truly empirical way of validating whether their recommendations are correct. For example, how do we know that a tamper switch required to be tested quarterly shouldn’t be tested weekly? Conversely, maybe a smoke detector that carries an annual requirement for testing should be tested every three years. The point is, if all ITM tasks were performed in a digital and shareable format, these agencies could make much more intelligent decisions around the frequencies of inspections. Critically, if data driven decisions are employed, customers and service providers can focus their time on the truly critical tasks.

- Capital planning.Think about how a fire alarm or sprinkler system is designed today. Typically, these systems have devices spread out to maximize coverage and minimize the number of devices needed to properly protect a building. However, ITM data has millions of data points, allowing us to plan these installation projects more effectively than ever before. Additionally, analyzing this data can give predictive information around when capital expenditures are expected.

- Business intelligence. One of the critical issues with deficiencies getting fixed in a timely manner is learning about these deficiencies quickly. Most compliance software comes with dashboarding and visualization tools that identify these issues as soon as they’re discovered. Furthermore, most systems allow tracking the repair process in real-time, giving the peace of mind that you’re maintaining compliance.

Additionally, with data analytics it is hard to determine what data is going to indicated until it is analyzed. This means that the fire protection community hasn’t begun scratching the surface of what compliance data can reveal about overall compliance management. As is the case with most industries, data has the possibility of truly revolutionizing the way inspections, testing, and maintenance are performed in the future.

Report Distribution and Customizability

The job of ensuring that a city has met all of its regulatory requirements around compliance is incredibly burdensome and can create an unmanageable task for authorities having jurisdictions/code officials. However, the digital transformation of the inspection process creates speed and transparency that has disruptive potential for how an AHJ/code official goes about ensuring the jurisdiction they’re responsible for has met all of these requirements.

For example, consider the process prior to the introduction of technology (which is still the reality in most buildings). Hundreds of thousands of inspection reports would be stored in customer filing cabinets with red ink highlighting deficient devices. The AHJ/code official has the insurmountable task of ensuring those deficiencies are remedied in a timely manner. The future state of digital inspections allows that when these deficiencies are found, they can easily be transferred to the people required to keep these buildings in compliance. Additionally, this information can now be aggregated and analyzed giving AHJs the ability to quickly digest and prioritize the issues throughout their area and action these items accordingly. Taking compliance information from storage cabinets to the cloud will truly disrupt how AHJs work in a positive way.

An additional problem plaguing this industry is the lack of report format standardization. This creates a number of different challenges for organizations spanning multiple cities and states. However, with the future of testing fire protection systems in the cloud, keeping track of these various requirements has never been easier. Furthermore, with more organizations adopting digital means for compliance, the governing bodies should move toward standardization for compliance documentation.

Moving the testing of fire protection systems to the cloud is not without challenges. For starters, training an entire industry on a digital means of doing their job is easier said than done. In many situations, this is a workforce accustomed to working on mechanical systems. Putting a laptop or smartphone in their hands and asking them to complete their documentation could be met with some resistance. Additionally, system connectivity is still a nascent concept and is inevitably going to present some technical challenges. For example, putting a fire alarm system in the basement of a skyscraper on the internet is an incredibly daunting engineering feat. However, as is the case in any industry, the technology will inevitably adapt and evolve to a point where one day, we won’t remember fire alarm systems that couldn’t connect to our smartphones.

It is critical for the fire protection industry to think about what a fully validated ITM process could mean for keeping people safe. This includes thinking about what a digitized ITM process will mean to the AHJs who have the painstaking task of keeping buildings safe. It is important to sympathize with the governing bodies who try to establish the proper testing frequencies and determine how to help this process become data driven. A good start in the process is to no longer accept pen and paper reports that come with little to no validation regarding how they were performed. Ultimately, the benefits far outweigh any negatives or challenges that go along with moving the compliance process to the cloud, and it is time that as an industry, we finally move beyond the filing cabinet.

By: Tyler Brown

Former Product Manager and General Manager of Xaap